With the engine out of our low-mileage SC, we could really take a look at all of the drivetrain and give it a once over. Unfortunately, one of our first checks—that of adjusting the valves—showed that we had an issue with our case studs. Several of them were broken.

With engine out and on the stand, the valve covers (upper and lower) were pulled off.

There were three broken studs that were visible with the covers off. The Factory tried several different stud materials during the 911s model run and these early SC Dilivar ones are known to be some of the worst of the lot.

Here's one of the broken studs and you can see where the crack propagated from a section where the outer surface had some corrosion—the darker spot on that crack is where the corrosion started eating into the metal before it finally let go completely at that point.

All three of the first broken studs had similar crack propagation patterns. Later Dilivar case studs were coated to prevent this issue.

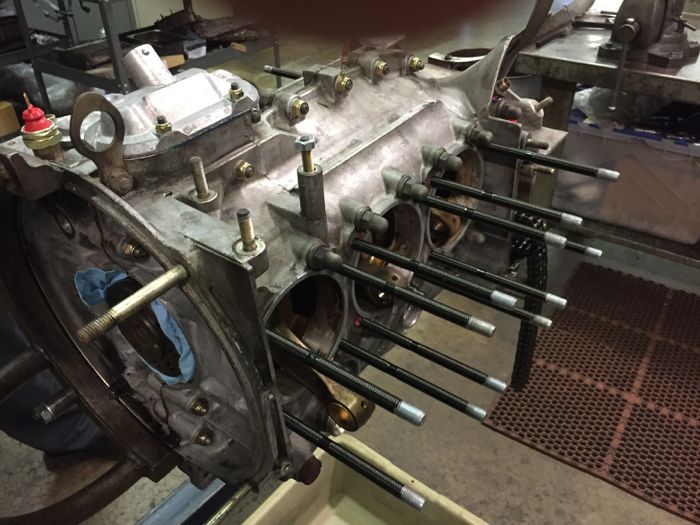

The bad studs were removed from the case by welding a nut to the broken nubs. Of course, this means all six piston and cylinder assemblies were removed from the case. We were now in pretty deep—although the case was not split open.

We replaced all of the studs with the full-threaded 10mm stud from the 993 Turbo.