Question:

I’m finishing up the rebuild on my 356B Super engine. It’s been a couple of years and just now I’m installing the fuel system. I have several banjo-bolts and can’t figure out which one goes where. Please enlighten me on banjo bolts. - P. Garvey, Concord, MA.

Answer:

Like many guys owning and working on 356s, you probably have a box of nuts, bolts and other fittings including a few banjo bolts. There were many banjos on Porsche engines, so it’s not surprising you have this question. If you are wondering, What’s a banjo bolt? See this video here. Porsche calls these "hollow bolts."

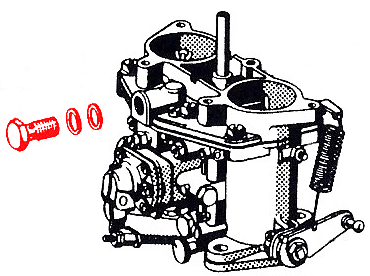

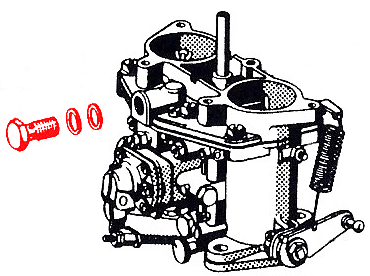

For 356 fuel systems there are only two bolts to worry about. First, for the carburetors (Zenith and Solex), the bolt looks like this photo:

The important dimension is the thread: 12 x 1,25. The length of the bolt is 22,45 and shoulder under the head is 12,00. With many original bolts, the head will be stamped with a “V” which denotes Vergaser, German for carburetor. Part number is 616 100 867 00 .

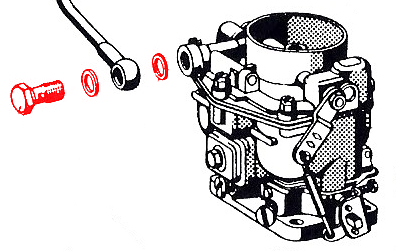

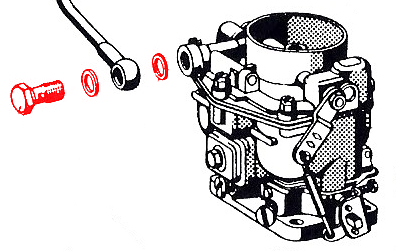

For fuel pumps, the bolt may look about the same but the thread is 12 x 1,50. Length is 24,00 and shoulder is 12,00. Part number is 900 175 020 01. Bolt looks like this below:

Note, there is no shoulder under the head, although the same sealing washer is used.

The fiber sealing washer for both sides of the banjo (ID 12,12) for both carbs and pump is part number 616 108 423 00. You’ll need seven washers per engine.

Incidentally, for early 356A engines, the 900 175 020 01 bolt is used in the Solex 32 & 40 carbs and also in the early fuel pump.

I hope this sorts out some of those banjo bolts in your Treasure Box of Fittings.

Regards,

Brad Ripley