Get 000 Magazine!

- By Devon Finsley

- Jan 8, 2026

1964. I took my first Porsche test drive in a used 1960 356 B Normal coupe. It was in amazing condition…Condor Yellow with rare coupe seats that were black with yellow inserts and decorative aluminum side trim along the body. The odometer read 38,269 miles. The sale price was $1,350.00.

I was an 18-year-old freshman in college…home for the winter Holiday break. The salesperson asked if I could drive a manual shift car. I replied, ‘Yes.’ He explained the four-speed shift pattern and asked if I knew what a tachometer was. I replied, ‘No.’ He said that’s OK…he’d show me the ‘dead center’ gauge and how it worked. I was a little nervous, but very excited to actually be driving a Porsche.

As we drove off the used car lot into traffic, he told me there were three things to ALWAYS remember:

He then instructed me to accelerate in 3rd gear as we approached a winding down hill curve to feel the grip of the Porsche through the turns. “This is what a 356 is all about! “ As we entered a flat stretch of road --he said, ”now get on the gas…take the rpms up to 4,500 and shift quickly into 4th gear.” I was now very nervous …already doing about 60 mph when the speed limit was 40! I went to shift into 4th and accidentally grabbed his left knee which was next to the shifter! Boy, was I embarrassed! I managed to recoup from my ‘faux pas’ and made the shift …then accelerated up to 80 mph. What a blast! We turned around and drove the exact route back …while I tried to keep my ‘rev’s up’ through the gears.

We arrived back at the dealership. I told the salesman I wanted to buy this Porsche. I gave the dealership $25.00 in cash to “hold the 356.” My father lent me $1,400 for the purchase. One week later, I was driving my Porsche 356 B coupe down Route 11 toward Tuscaloosa, Alabama…looking for oncoming Porsches to ‘blinken lassen’ while I was concentrating on keeping my revs up! I never saw another Porsche during the entire trip back to school.

Spring 1964. I was home from college for the summer…and driving my 356 on the brand-new Interstate 95 North through Maryland heading to New York…and a fantastic summer job at the New York World Fair in Flushing Meadows. I happened to glance across the grassy median filled with hundreds of sprouting daffodils -- and saw a red 356 cabriolet heading south on the Interstate-- ‘die Scheinwerfer aufblinken’--at my Porsche. I was so excited, I blinked twice! The driver and passenger in the cabriolet waved as we passed each other…I was able to get a wave back--It was my first Aufblinken!

Some things have changed over the years. I suspect today, many new Porsche owners don’t know about the multiple use of the signal stalk when they take delivery from the Porsche dealer. Owners might think that flashing the headlights might be a signal that danger exists on the roadway or perhaps the ‘cops’ are using radar ahead…Slow Down!

Out of curiosity, I did some online research to see if anyone was mentioning ‘blinking.’ To my surprise…”blinking “and “flashing” has generated a lot of comments. Here’s a sample of what some Porsche owners have noted:

October 2025. I was driving north on Interstate 95 in my 1999 986 Boxster heading for the Sixth Annual PCA Ocean City, New Jersey Boardwalk Reunion…and at the exact location 61 years later—I glanced across the grassy median dotted with pansies--looking for that red 356 Cabriolet.

Blink…Blink

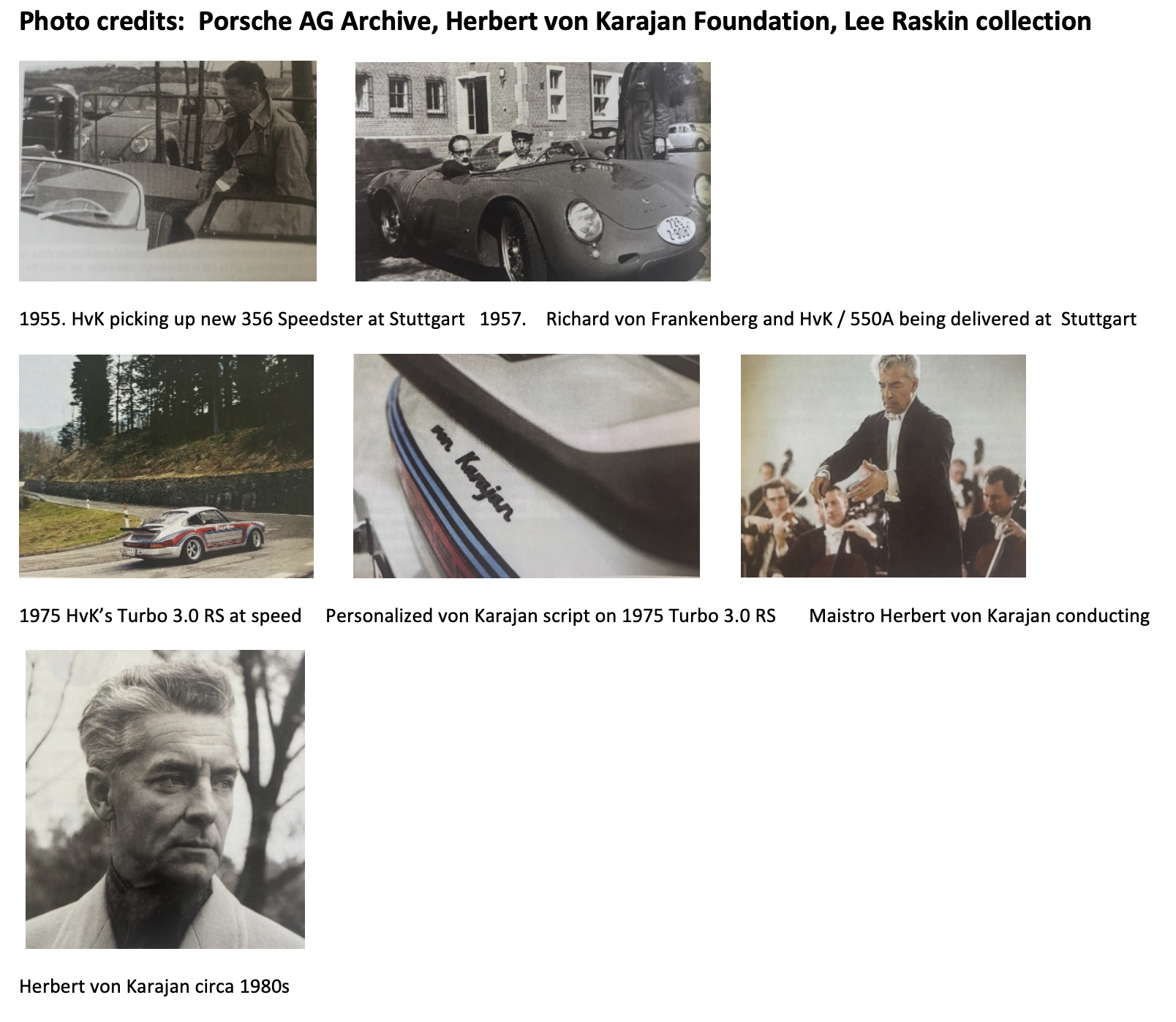

As a Porschephile, Herbert von Karajan was as passionate about the marque as he was about his professional life – being the most-renowned philharmonic conductor to emerge from Europe during the post-war era.

Von Karajan possessed the legendary status of being one of the earliest Porsche celebrities…along with actors James Dean and Steve McQueen—to get behind the wheel of a TYP 540 Speedster. Small in stature; however, he was regarded by the European motorsports’ media as an aggressive Porsche pilot, albeit with a very quiet and unassuming manner.

The Maestro’s first Porsche was a white 356 pre-A 1500 Normal Speedster, VIN 80481, that he personally picked up from the factory at Stuttgart in April 1955. For several years, he drove the Speedster everywhere even during the European winters –in the freezing cold and snowy weather.

In 1957, a fellow Porsche owner, Gottfried Koeschert, suggested to von Karajan that he could probably order a new TYP 550A equipped for public driving directly from the Factory. So, von Karajan called his friend, Ferry Porsche and asked to purchase a TYP 550A. After some deliberation, Ferry agreed to sell him a used 550A racer. Von Karajan accepted the offer. Porsche 550-0131 was personally delivered to von Karajan by the factory driver and editor of Christophorus, Richard von Frankenberg at Stuttgart Zuffenhausen. Von Karajan was elated!

As part of the sale agreement with von Karajan, Ferry told him that the Salzburg Porsche dealer would service and maintain the 550A. The dealership also agreed to store the 550A during the winter months. To von Karajan…that sounded Super!

Researching the race history of Vin 550-0131, I found it had been entered by the Porsche Werks at the 1957 Le Mans and driven by Hans Herrmann and Richard von Frankenberg. Unfortunately, the 550 A #33 became a DNF with ignition problems after being solidly in 13th place at hour eight.

After owning the 550A, von Karajan became the caretaker of other Porsche racers. In 1959, he replaced 550-0131 with a 1958 TYP 718 RSK. In 1964, he acquired a Porsche 904 GTS, and then a very rare 1975 Porsche Turbo (TYP 930) 3.0 RS.

The 1975 Porsche Turbo was built by Porsche’s Special Order Department for von Karajan using a Carrera RS body with a RSR racing chassis. The Turbo was painted in the Martini-esque livery and it had an exclusive ‘von Karajan’ script affixed onto the body just under the whale tail.

Von Karajan remained a close friend with Ferry Porsche and he was one of the first private clients who Ferry called when an early-production Guards Red 959 became available. Interestingly von Karajan’s wife, Elliette, expressed her concern about the expensive purchase price of this 959. Presumedly, she told Herbert, “You’d better sell more records,” and it is said that von Karajan responded by increasing his concert ticket prices. During his lifetime, von Karajan was estimated to have sold 200 million records!

Herbert von Karajan loved his 959, and so much so, he later purchased a second 959 for his collection. In addition to the two 959s, he owned several 911s.

Doing a back flip, von Karajan’s early life is important to note. He was a young Austrian native studying music at the Mozarieum University in Salzburg during the 1920s. His professional conducting debut took place in 1929. He was appointed to a conducting position in Ulm, Germany, and was then appointed Kapellmeister at Aachen, Germany in 1934, where he remained until 1941.

Von Karajan had been persuaded to become a Nazi party member in the 1930s. During the early years of the war, he opposed the ideology of the Third Reich and fled Germany with his family to Milan, Italy. He was exonerated by an Allied tribunal after the war ended in 1945. Von Karajan returned to Austria to become the principal conductor for the Vienna Philharmonic for the next four decades and performed regularly with the London Philharmonic, and Berlin Philharmonic, until his death in July 1989 of a heart attack at age 81.

In 2015, at the Los Angeles Literature and Toy Meet, I was talking with a long-time 356er friend, George Kehler, II of Johnson City, Tennessee. We were conversing about celebrities who owned 356 Porsches and George mentioned that the legendary European philharmonic conductor, Herbert von Karajan once owned an early 356 pre-A Speedster around the same time as actor James Dean.

George also recalled: “My father, George Kehler, studied piano in Salzburg, Austria, with the same piano instructor as Herbert von Karajan, the late and legendary Berlin/Vienna conductor. The professor teaching piano at the time was named Franz Ledwinka…whom I met in 1969. I recall that Professor Ledwinka taught at the Mozarteum in Salzburg, Austria from which both von Karajan and my father graduated.”

A Renaissance man, von Karajan inspired the best of his orchestras and desired the best in life: his Porsches, houses, clothing styles, etc. My father always spoke highly of him.”

I was fascinated with George Kehler’s recollection…which led to this amplified storytelling.

Herbert von Karajan was a unique individual—controversial but a dominant figure who shaped the perception of sound for an entire generation of musicians and music devotees during the 20th Century.

Wilfried Strehle, the principal violinist under von Karajan recalled, “You can still hear this incredible passion, this thrust, this force, which might also explain –in metaphorical terms – his fascination for Porsche.”

A committed Buddhist, von Karajan was a believer that death did not mark the end of a life. I would like to imagine the Maestro is still passionately conducting in front of all his cherished Porsches – which are performing at ‘redline’ with distinctive and resounding exhaust notes…Vroom, Vroom!

*Lee Raskin is an internationally recognized Porsche 356/550 historian / author of acclaimed photographic biographies.

Copyright Lee Raskin

PEGASUS…The Winged Horse

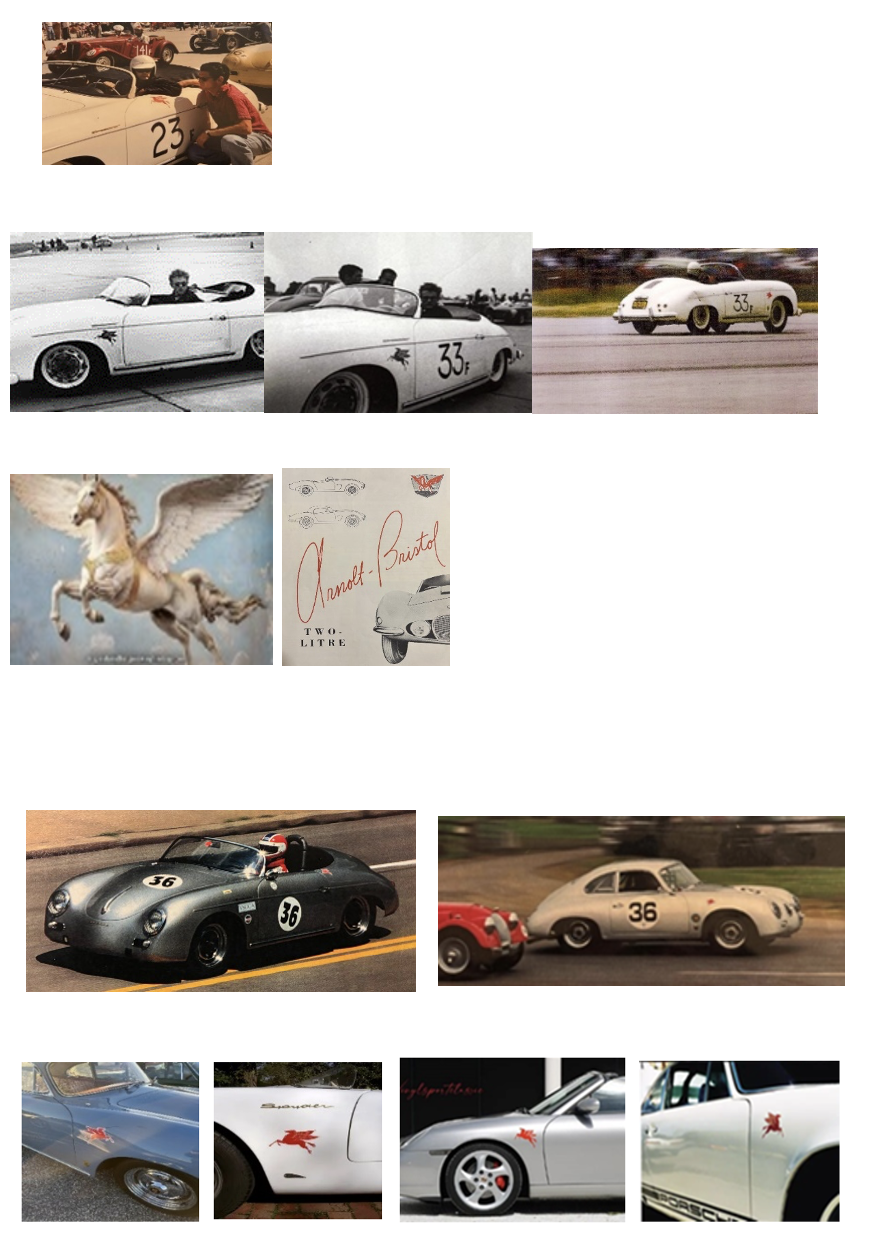

Some Porschephiles may have seen photos of a PEGASUS decal displayed on James Dean’s Porsche 356 Speedster during the 1955 California Sports Car races...and wondered what the PEGASUS decal represented?

In March at Palm Springs, James Dean placed PEGASUS decals on his Porsche Speedster…two at the top of each door.

(Photo: James Dean awaits the start of the F-Production / F-Modified Feature Race while getting instructions from his crew chief, Bill Stevens.)

Later, at Santa Barbara in May, Jimmy placed a PEGASUS decal on the left front and right front fender of his #33 Porsche Speedster. The PEGASUS decals on James Dean’s Porsche at the Santa Barbara races became highly publicized images over these past seventy years.

(Photos: 1. James Dean arriving at the Santa Barbara Races…he has just fueled up and received two Pegasus decals PEGASUS to put on his Speedster. 2. James Dean on the grid prior to a F-Production practice race. 3. James Dean at speed during the feature F-Production race. Photos. Lee Raskin archives.

How cool! The media portrayed actor / racer James Dean as a real trend setter—writing that he was sponsored by the Mobil Oil Company… and he displayed the PEGASUS decal on his Porsche 356 Super Speedster to capture even more media attention.

I found that tale was incorrect…as there was more to the Pegasus’ decal story: Pegasus, the flying horse, was born out of Greek mythology during the Dark Ages, circa 1200-800 BCE. Pegasus was depicted as a mythical winged stallion who was immortalized as a constellation of the northern hemisphere.

(Photo: Pegasus Greek Mythology, Wikipedia.)

The origin of the modern-day Pegasus logo came from the Vacuum Oil Company, which first used the Pegasus in South Africa during 1911 --as a symbol of speed and power. After a corporate merger of Vacuum Oil with Socony Oil in 1931, the Pegasus logo was adopted as the U.S. trademark and a sign mark for thousands of Mobilgas stations throughout the United States.

During the early 1950s sports car racing grew in popularity, especially in Southern California where the California Sports Car Club (CSCC) and the national Sports Car Club of America (SCCA) hosted amateur weekend racing on make-shift road courses located primarily at municipal airport venues and on U.S. Air Force bases throughout the U.S.

In 1954, Stanley “Wacky” Arnolt founded a motorsports entity in Chicago, offering the Italian Bertone designed Arnolt-Bristol competition roadster and Deluxe coupe to the public. It was the first American sports car to have a Pegasus winged horse design as its official emblem. Today, Arnolt-Bristol models have become a coveted and highly collectable sports car.

(Photo: 1955 Arnolt-Bristol four-page color brochure, Lee Raskin Archives.)

During the same year, Socony Mobil Oil saw a terrific opportunity for sponsoring amateur racing events and to market their ‘high test’ gasoline in Southern California.

They gave away FREE premium gas to all the drivers at these racing venues …with the proviso that a Mobilgas PEGASUS decal would be placed by the recipient driver in clear sight on his/her race car throughout the race weekend. It was genius!

James Dean saw this Mobilgas promotion as a nice gift –an opportunity to accept FREE racing fuel at the Cal Club and SCCA races.

He artistically placed PEGASUS decals on his Porsche 356 Super Speedster for all to see and to photograph.

Decades later, I emulated James Dean’s motorsports endeavors when vintage racing my 356 Porsche Speedster and 356 Sebring coupe…I too wore the Pegasus decal as far back as 1990.

(Photos: 1. Lee Raskin / 356 A Speedster #36 at the Pittsburgh Vintage GP, 1994. 2. Lee Raskin / 356 A Sebring coupe at Summit Point Raceway,WV, 1996.)

Recently, Porschephiles were actively looking for reproduction PEGASUS decals … and now they are available…as seen on vintage 356s and contemporary 900 series Porsches at local Cars and Coffee events…where their owners desire to be part of the nostalgic James Dean / Porsche era…Vroom, Vroom!

Photos: Lee Raskin archives

Copyright Lee Raskin 2025

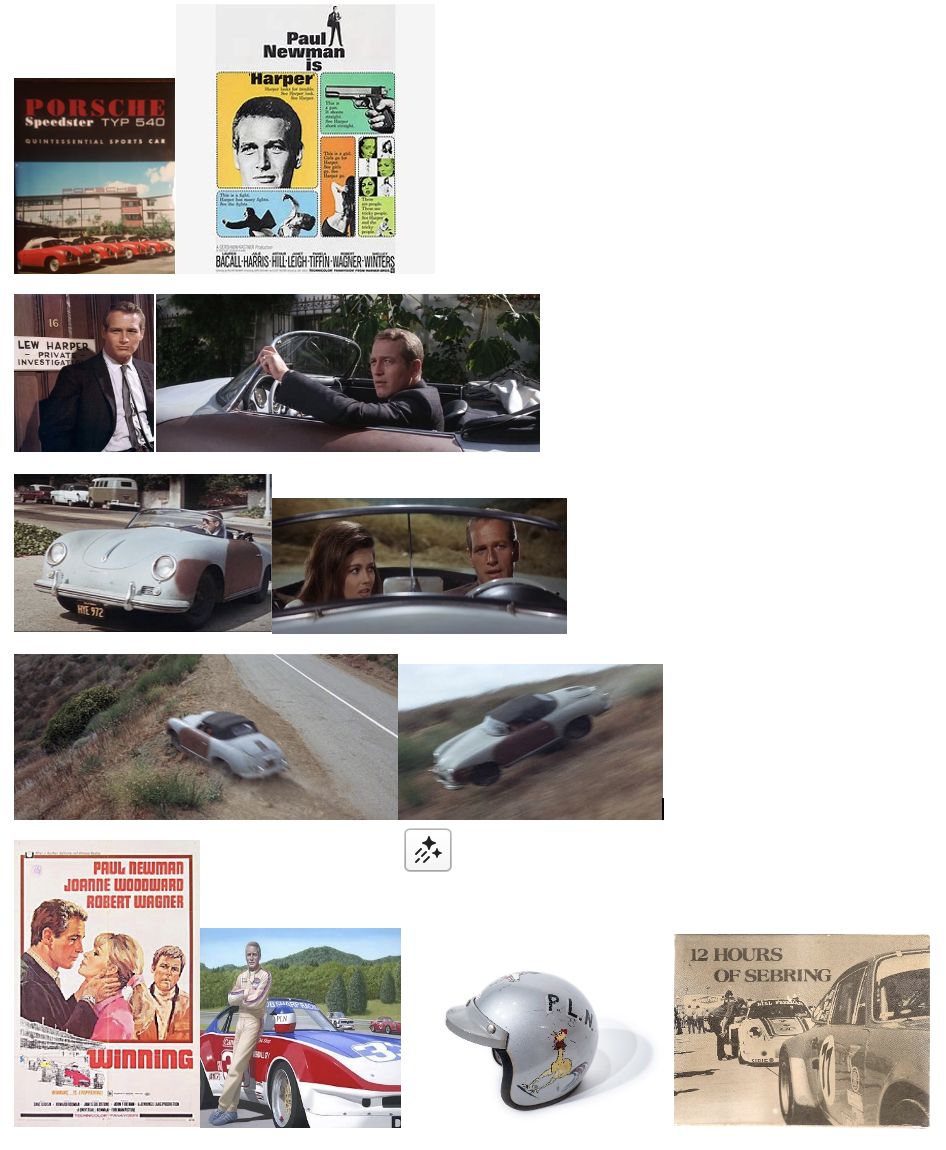

It was December 2003. The telephone rang and I answered it. The distinct voice at the other end, said, “Hi Lee, this is Paul Newman…I understand from Bob Snodgrass (then President / CEO of the legendary Brumos Porsche dealership in Jacksonville, FL) that you want to interview me for a Porsche 356 Speedster book.”

I was thinking, “How cool is this?”

At the time of Paul Newman’s telephone call, I was busy researching and writing a chapter for a forthcoming co-authored publication, PORSCHE Speedster TYP 540: Quintessential Sports Car.

The chapter, entitled, Celebrities Pose with a Rising Star, was about world-wide celebrities who owned and drove, and may have even raced Porsche 356 Speedsters. My candidates for this chapter were: Sean Connery, James Dean, Steve McQueen, Richard Boone, Herbert von Karajan, Janis Joplin, and of course, Paul Newman.

I had met Paul Newman at Sebring in 1977 when I ‘crewed’ for the legendary Bruce “King Carrera” Jennings’ 911 S racing team.

Nearly four decades earlier, actor Paul Newman, played the acting role of Lew Harper, a Los Angeles private detective who drove a 1956 light blue/primer Pre-A 356 Speedster in the mystery-thrilling movie, Harper.

Paul was engaging from the start of our conversation…mentioning that he hand-picked this ‘clapped-out’ ’Speedster from a group of European sports cars that Pete Smith of Bob Smith VW and Porsche in Hollywood had assembled and brought over to the Warner Bros. film set.

This Speedster, in Newman’s opinion, was the car best suited for Lew Harper’s quirky detective role in the film.

Paul recalled that he had never owned a Porsche 356 before filming Harper. Paul also mentioned, “that ‘bathtub’ was sure fun to drive…it had a lot of oversteer.”

The 356 Speedster was an original California “black plate” car, that had been someone’s very tired daily driver.

Paul and I agreed this Speedster was the first-ever Porsche to be featured in a co-starring role for a full-length Hollywood film –over a decade before a 1957 Speedster appeared in Jane Fonda and Jon Voight’s Coming Home (1978). Paul commented, “it was my first experience driving a 356 Speedster, as well.”

Perhaps the most memorable scene in Harper for every Porschephile – happens when the Speedster is ‘hot-wired’ by Betty Fraley, played by Julie Harris. Fraley, driving the stolen Porsche, races up the dusty canyon road with Lew Harper and Albert Graves, played by Arthur Hill, in hot pursuit.

Trying to avoid a serious collision with a utility truck stopped in the middle of the road, Fraley suddenly veers left and drives straight over the side of the canyon’s steep hill…a breath-taking sight!

Paul laughingly recalled, “during the filming of the Fraley crash, the Speedster was wired for the throttle to be wide-open. The crew started the engine, put it into first gear...and the rest became film history as the Speedster took off like a rocket.” The Porsche managed to stay on all four wheels as it bounced along the canyon hillside …sometimes in full flight… with the 356 Speedster finally coming to rest a hundred feet below. In the film, the Speedster crash killed Betty Fraley.

Paul mentioned that he didn’t get fully involved with sports cars until after the filming of Harper. It was in the late ‘60s that he had his first driving experience at Lime Rock Park, near his Connecticut home. His local mechanic had a 356 Porsche coupe and Newman drove it around the track at speed with ease. Later, Paul Newman purchased a Porsche Super 90 coupe while living in Southern California.

Paul’s passion for speed began while he was filming the ‘Indy-car’ racing movie, Winning (1969) in which he also drove a Porsche. His wife Joanne Woodward co-starred with Paul in the movie.

He became a pretty good racer during his late 40s, driving for the Bob Sharp-sponsored Datsun/Nissan dealership. Paul won the C-Production SCCA Championships in 1979, 1985, and 1986.

Paul’s first Porsche racing experience came in 1977 at Sebring’s 12 Hour Endurance Race where he co-drove with Bill Freeman in the pink and white #2 Beverly Hills Porsche 911S in GTU. Many of the 15,000 spectators were not even aware that Paul Newman was racing at Sebring. He was listed in the program simply as P.L. Newman. The media wasn’t dialed into who P.L. Newman was either. Paul’s open-faced Bell helmet had the initials: P.L.N. hand-painted on it along with three cartoon characters –a rooster, a chipmunk, and a coyote.

The #2 Freeman/Newman Porsche qualified 41st on the starting grid behind Bruce Jennings’ #77 911S. Throughout the 12-hour race, the Porsche had its share of minor problems and spent precious laps in the pits for repairs. In the final hours of the race, Newman drove the Porsche around the 5.2-mile circuit in the dark with two of the three steering wheel spokes completely broken. Bill Freeman and Paul Newman finished 30th overall and 11th in the GTU class while completing 150 laps.

This was to be Paul Newman’s first and only Sebring 12 Hour race. Paul later recalled, “Sebring was one tough race…that I actually loved to hate.”

Paul proved his driving ability as a professional Porsche racer with his second-place podium finish and a class win at the 1979 24 Hours of Le Mans co-driving with Rolf Stommelen and Dick Barbour-- who sponsored the Porsche 935. Paul also won a major endurance race co-driving with Dick Barbour at the 1981 24 Hours of Daytona.

Paul Newman’s interest in racing accelerated with the Newman/Haas racing program competing in the open wheel series with CART/Champ cars, and the IRL/Indy cars from 1983 to 2008.

Paul Leonard Newman was one of the greatest actors of the 20th century, a world championship motorsports racer, and truly a great guy.

Paul Newman sadly passed away, dying of lung cancer in September 2008 at age 83.

Remembering P.L.N. Race in Peace.

Epilogue: There were two Pre-A Speedsters that were used during the filming of Harper. The blue and primer colored Speedster that was driven mainly throughout the film and was not sent over the cliff…actually survived to be fully restored…and it lives on!

Copyright Lee Raskin, 2025

PORSCHE Speedster TYP 540 Quintessential Sports Car, 2004

HARPER Movie Poster, 1966

Photo credit Warner Bros. Archives

Lew Harper driving his Porsche 356 Speedster

Photo credit Warner Bros. Archives

Paul Newman playing private detective Lew Harper with his 1956 356 Porsche Speedster.

Paul Newman and Pamela Tiffin driving in the Porsche 356 Speedster

Photo credits Warner Bros. Archives

356 Speedster crashing down the canyon hillside.

Photo credit Warner Bros. Archives

Winning Movie Poster starring Paul Newman, Joanne Woodward, Robert Wagner

Photo credit: Universal Pictures Archives

Paul Newman / SCCA Driving Champion at Lime Rock Park

Paul Newman / Bob Sharp Racing Team Archives

Paul Newman and Bill Freeman’s #2 Porsche 911S

Photo credit: Lee Raskin, Sebring 1977

P.L.N.’s racing helmet at Sebring 1977

Photo credit: silodrome.com 2023

Paul Newman racing at Le Mans, 1979

Photo credit: sportshistoryweekly.com 2024

Through My Rearview Mirror

Carrera

The Porsche factory-and Fletcher Aviation sponsored 550 Spyder 4-cam 1500cc powered racing team at the Carrera Panamericana Mexico Road Race, 1954. (Photo credit: Porsche AG)

Carrera—Most Porschephiles associate this name with a 900 series, those wide-bodied Porsches with flared fenders and bedecked with front spoilers and large rear wings. However, the Carrera is named, not for a body style, but an engine type that is as old and prominent as the Porsche marque itself.

CARRERA is a Spanish word that means, “road race”- a competition where one strives to be a first-place finisher.

So why is this Spanish name so boldly imprinted in script on so many German-made Porsche models?

The year was 1952. General Dwight D. Eisenhower was elected President of the United States…mainly because he promised to bring the boys home from the Korean War. Interest was at a mere 3%. The Yankees beat the Brooklyn Dodgers 4 games to 3 to win the World Series—and Dr. Ferry Porsche commissioned Ernst Fuhrmann to build a new high performance engine for his race cars. Fuhrmann's new 1500cc, TYP 547 four-cylinder engine used four Hirth overhead roller bearing camshafts to deliver considerably more power than the original VW-based mills.

This engine was first bolted to the Factory’s open two-seater racers for the 1953 race campaign. Thus, the Carrera engine was born and proudly named in honor of the grueling five-day, 1,934-mile Carrera Panamericana Mexican Road Races that were held from 1950 to 1954. Factory-prepared Porsches participated in the Carrera Panamericana Road Races with pushrod powered 550s to finish with a class victory in 1953.

For 1954, the Fuhrmann Four Cam engine was installed in the new TYP 550 Spyder for the Porsche Werks’ endurance racing program. The result was a winning combination of engine and body design that became competitive on the international racing circuits of Reims, Nurburgring, Le Mans, and the Carrera Panamericana Mexican Road Race.

Carrera engines were manufactured at Stuttgart-Zuffenhausen with 110 horsepower from 1.5 litres; and later the engine displacement was increased to 1.6 litres and produced 150 horsepower. Racing successes were achieved among the TYP 550/718 Spyders, TYP 540 Speedsters, and TYP 356 Coupes at major international events.

In 1961, the Factory developed a 2-litre engine that was displayed to the public at the Frankfurt International Motor Show in a newly designed TYP 356 B GS/GT Coupe, which was more aerodynamic than the previous A and B production models.

This racing model had a 1966cc Carrera engine which featured twin ignition systems and a pair of Solex carburetors. The 356B Carrera GS/GT coupe cranked out 152 horsepower at 6200rpm with a top speed of 130 miles per hour.

Porsche continued to use the Carrera 2 litre four cam engine (and later, a flat eight) to power their first ever fiberglass and ladder frame bodied sports racing car --the TYP 904 GTS. The new 904 GTS, designed by Ferdinand “Butzi” Porsche, became an immediate success for the Werks’ FIA GT racing class during 1964-1965 at Reims, Sebring and Le Mans. The 904 GTS was also successful in international rallye competition.

In 1966, Porsche debuted Ferdinand Piech’s designed TYP 906, named the “Carrera 6.” became homologated for FIA racing. The new Carrera 6 employed an aerodynamic unstressed fiberglass body over a light weight tubular space frame chassis, with the flat-six Carrera engine from 904/6 variants. The Carrera 6 long tail would win the 1966 World Sportscar Championship and the 1966 - 1968 European Hillclimb Championships.

In 1973, the Carrera name officially appeared on the last of the long-hood 911s with the Carrera RS. The 2.7-litre Carrera RS was a built as a limited production special to meet homologation rules for various racing organizations. It was available in several different versions including a lightweight Sport (200 made) and a more street oriented Touring version (1308 produced) as well as an even more limited production full race version—the RSR (less than 60 made.) The street legal Carrera's 2.7 litre engine churned out 200 horsepower while having a top speed of 150 mph in street form. It was the first 911 to feature a small "ducktail" rear spoiler to help the rear of the car stay planted at these heady speeds.

That rear spoiler became a defining feature of the Carrera, and by 1975, it grew an even larger tail, with an upturned rubber lip that protected the delicate fiberglass engine lid and gave a little more downforce. Displacement was bumped to 3.0 litres in 1974 with the change to the G-Body, which unfortunately also gained the heavier 'impact bumpers'. In 1976, the Carrera picked up a turbocharger and a new name: “Turbo Carrera.”

The Turbo Carrera was a beast; it tested out at 256 horsepower with a top speed of 155 miles per hour. The turbocharged engine was truly amazing, as the exhaust driven turbine wheel developed speeds of up to 90,000 rpm, pre-compressing air to a density of 11.4 psi. Of course, the fuel injection was commensurately modified to maintain the proper air and fuel ratio.

Stuttgart-Zuffenhausen continued to promote the legendary Carrera name for over five decades with the production of the following models:

TYP 911 Carrera G-Series…1974 to 1989 (1974-1976 Carrera 2.7), (1978-1983 911 SC), (1984-1989 Carrera 3.2)

TYP 924 Carrera….(1980 GT), (1981 GTS)

TYP 930 Carrera…1975 to 1989 G-Series, (1975-1977 3.0 Turbo H6), (1978 -1989 3.3 Turbo H6)

TYP 964 Carrera….1989 to 1994 (Carrera 4 / Carrera 2, RS / RS America, Targa, Cabriolet models)

TYP 993 Carrera…1994 to 1998 (Last of air-cooled engine . Carrera S / Carrera 4S / Turbo / Turbo S)

TYP 996 Carrera…1998 to 2006 (2002 996.2 introduced with Targa and Carrera 4S models)

TYP 980 Carrera… (Carrera GT) 2003 to 2006 (1,270 units built)

TYP 997 Carrera…2005 to 2012 (2005 -2008 997.1, 2009-2012 997.2 becomes a facelifted version)

TYP 991 Carrera…2012 to 2019 ( 991.1 / 991.2/ T). Seventh generation with longer wheelbase, wider track)

TYP 992 Carrera…2019 to present. Eighth generation. (2021 introduced 992 GT3 / 2021 992 GT3 RS/ T in 2023)

CARRERA. A distinctive name and script representing Porsche’s racing legacy…one of prestige and perfection…Driven by Dreams.

*Lee Raskin is an internationally recognized Porsche 356/550 historian and an author of acclaimed photographic biographies.

Copyright Lee Raskin, 2025.

Portrait of the Month

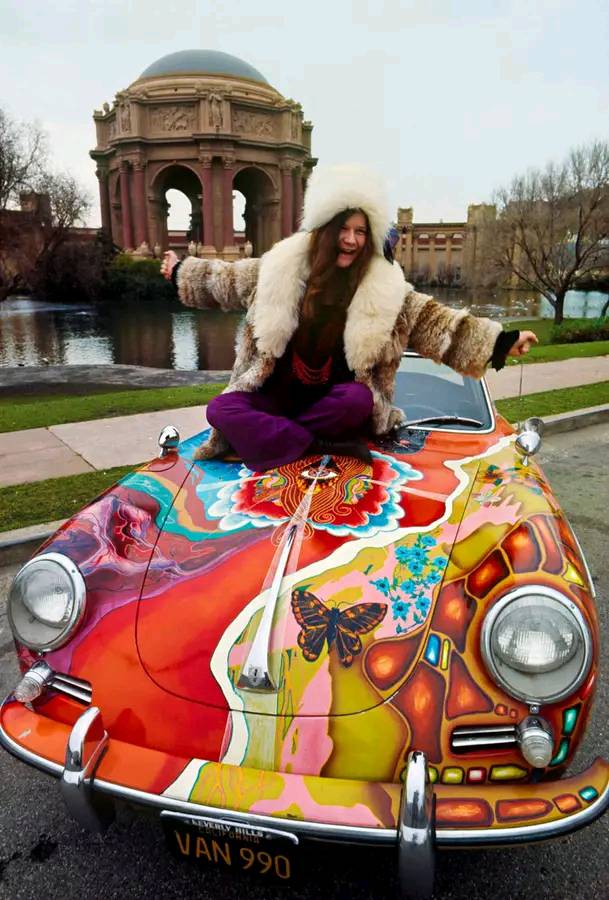

Janis Joplin

Janis Joplin at the San Francisco Palace of Fine Arts with her psychedelic 1964 Porsche 356 C Cabriolet,1968. Photo credit: Jim Marshall / Estate of Jim Marshall.

Oh Lord, won’t you buy me a Mercedes Benz?

My friends all drive Porsches, I must make amends.”

This is a telling story…about the Queen of Psychedelic Soul who also owned and loved to drive her 356 Porsche.

This year commemorates the 55th Anniversary of the death of the most iconic and successful rock performers of the late 1960s –Janis Joplin, who tragically passed away on October 4, 1970. Amongst Porsche enthusiasts, she is also known for her beloved 1964 Porsche 356C Cabriolet.

It was September of 1968. Janis Joplin, lead singer of her Big Brother and the Holding Company rock band was in Los Angeles recording their songs. She drove past the Estes-Zipper VW and Porsche dealership on Wilshire Boulevard in Beverly Hills and decided to take a test drive in a used 1964 Porsche 356C cabriolet. She fell in love with the Porsche and purchased it on the spot for $3500. It was painted the off-white Dolphin Grey with a black interior and had a black folding cabriolet top.

Janis decided to personalize her Porsche, like James Dean did with his 550 Spyder; subsequntly asking Dave Richards, a close friend and “roadie” with her band, to customize the 356 Cab as a kaleidoscopic mural.

Richards transformed the Porsche into what he called, ‘The History of the Universe,’ a unique mobile work of art. The dramatic graphics depicting butterflies, jellyfish, a caricature of Janis Joplin with her band, along with her Capricorn sign and the ancient third eye symbol. The Porsche immediately became identified with the Psychedelic Queen, wherever she drove in LA or in San Francisco and especially to her performances.

After Janis Joplin’s untimely death in 1970, the Porsche wound up with her former manager, Albert Grossman, who drove it for several years in New York until it became in disrepair. Joplin’s siblings took it back and had it repainted Dolphin Grey. Her brother Michael noted, “Besides Janis’ music and legacy, her Porsche is the most visual and important piece of memorabilia that exists.”

During the 1990s the family decided to have the Porsche repainted again as “The History of the Universe,” and commissioned artists Jana Mitchell and Amber Owen to do the honors. Historic photos were used to recreate the psychedelic livery.

The Porsche was then loaned for a long-term display at the Rock and Roll Hall of Fame and Museum in Cleveland.

"It seems like such an extension of her personality-beautiful and colorful and fun,” related a curator of the Rock and Roll Hall of Fame. “When I look at it, I see Janis in it, with the top down, with her dog, George, in the back seat, driving around the Haight. I really see it as an extension of Janis.”

After two decades…having been viewed by over half-million visitors per year, the family decided to take the Porsche out of the Hall of Fame Museum.

In December 2015, the family consigned the Porsche for a RM Sotheby's auction to be held in New York City. Auction experts estimated the psychedelic Porsche would fetch between $400,000 and $600,000. The iconic ’64 Cabriolet proved them wrong, as the bidding went well beyond those values and was sold to an undisclosed buyer for $1.76 million. It set a new record for the highest price paid for a production 356 Porsche model.

Today, Janis Joplin’s 1964 Porsche Cabriolet, VIN 160371 remains one of the most iconic production 356 Porsches owned by a celebrity…along with James Dean’s 1955 Porsche Super 1500 Speedster, VIN 80126, and Steve McQueen’s 1958 Porsche Super 1600 Speedster, VIN 84855.

*Lee Raskin is an internationally recognized Porsche 356/550 historian and author of acclaimed photographic biographies.

Copyright Lee Raskin 2025

Through My Rearview Mirror

Introducing Author Lee Raskin

We ran across this orange 1968 Sports Purpose style 911 at Autokennel and came away very smitten. They say it's hard to sell a car that's been modified to your specific tastes—but this one is so beautiful, it's surely the exception.

Learn more here: https://autokennel.com/?featured_vehicle=1968-porsche-911-sport-purpose-coupe-2-5l-aluminum-high-compression-twin-plug-1900-lbs-255-hp

This 1974 Porsche 914 2.0L Targa, finished in Sepia Brown with a striking two tone tan interior, represents what many consider the best iteration of the four-cylinder 914 lineup. Fully serviced in February 2023 by Jacks German Auto Service in Fountain Valley, California, this mid-engine Porsche is ready for its next owner to enjoy. It is for sale at European Collectibles in Costa Mesa, California.